Production

Ecology and Environmental protection

-

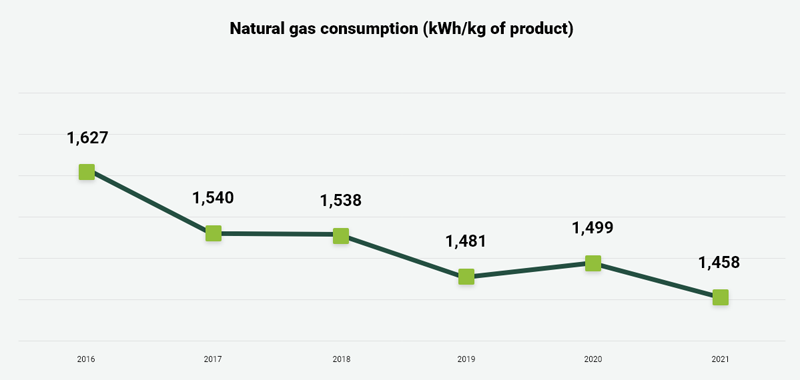

We use energy effectively

We use energy-saving technologies and meet ISO 50001 standards.

-

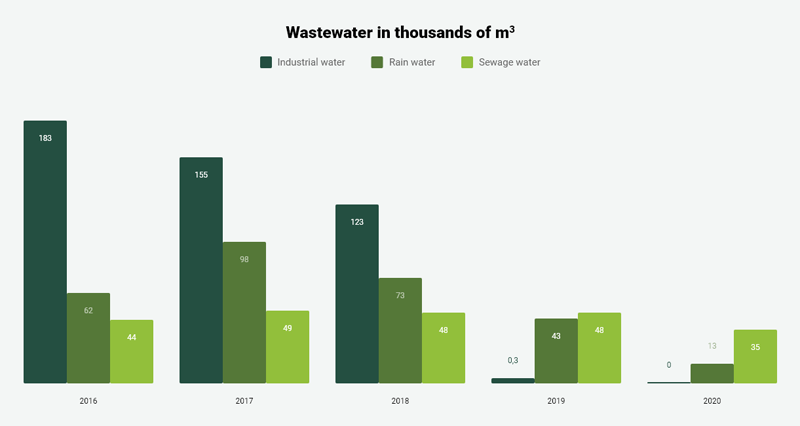

We conserve water resources

We reduce water consumption in every part of our production process.

-

We use waste heat

Thanks to waste heat, we save up to 15% of gas during drying.

-

We recycle our ceramic waste

We return shards, filter dust, and ground tiles back to production.

The ecological approach in production is reflected particular in the use of waste heat generated during the firing of our products, the recycling of our waste in wastewater treatment plants and the use of waste shards as part of our production mixture recipes.

- Our goal is to produce ceramic tiles of the highest (1st) quality with maximum efficiency.

- RAKO products have always been and are synonymous for quality thanks to years of expert knowledge, know-how of production processes from raw materials, processing, firing, and storage.

- Prerequisites for high production efficiency and 1st quality profitability

- Excellent knowledge of science and technology of the industry

- Rapid inter-operational checks on input raw materials

- Monitoring of production processes

- Optimisation and continuous checks of product properties

- Strict final product inspection

- Investments versus production quality

Every investment in new technology represents a significant shift in achieving and monitoring production quality, leading to an increase in our production efficiency.

- Investments in digital technology enable statistical evaluation and production improvements

- Clever decoration of our products as well

- We have implemented our ISO 9001 production quality management system

Download

- CQS - ISO 9001 (EN) (PDF; 593.67 kB)

- IQNet - ISO 9001 (PDF; 662.08 kB)

- The aim of most investments and innovations in new technologies is to effectively reduce our energy and water consumption and use waste heat (heat recovery units).

- Together with increasing yields and production efficiency, we are promoting the progressive reduction of waste and full use of raw materials.

-

Significant investments in new technologies

- Use of waste heat for heating of production facilities and for service water heating

- Waste heat from furnace flue gases is used in our production plants

- It is a heat source for drying ceramic sludge in spray dryers

- Minimal downtime and production interruptions - maximum heat recovery

- The ecological approach in production is reflected in particular in the use of waste heat generated during the firing of our products

- We recycle our waste in wastewater treatment plants and using waste shards as part of our production mix formulations.

- Our company is certified by the ISO 50001 energy management system

Download

- CQS - ISO 50001 (EN) (PDF; 592.58 kB)

- IQNet - ISO 50001 (PDF; 662.56 kB)

- Energy policy (PDF; 51.18 kB)

- We invest in more efficient technologies such as dry calibration.

- We use a closed technical water cycle.

- We have maximum control over water consumption in every part of our production process.

- We use rainwater.

- We biologically purify technical water.

- With the change in product calibration technology, our water consumption was reduced to 0 from the original approximately of 1,300 m3 of clean, potable water per year.

- New press cooling technology where the consumption of potable water has been reduced to the minimum by using other media with increased cooling efficiency (along with a reduction in equipment noise).

- As of 2019, industrial wastewater is being recycled for the production of ceramic sludge. It is used as a mixing water at the mass preparation plant and returned to production.

- Water consumption in our individual production processes is carefully monitored. In 2019, the online Q-max consumption tracking system was implemented.

LUBNÁ U RAKOVNÍKA Plant

The plant uses its own groundwater source. Wastewater from its sanitary facilities and food preparation is treated at a biological wastewater treatment plant. A recycling station has been built at the RAKO 3 plant to help save process water. It is used to clean water from the technology. The purified water is returned to the beginning of our production process. The purified water is also used for washing process equipment and floors. The technical water "circulates" in the plant, thus eliminating the discharge of process wastewater.

CHLUMČANY Plant

In the summer of 2019, rainwater catchment was implemented in a system of sedimentation tanks.

Wastewater reduction process at one of our plants in connection with the efficient return of technical water back into the production process.

The purified water is returned to the beginning of our production process.

- We invest in new technologies with more efficient gas combustion.

- We make maximum use of waste heat, there is no need to burn additional gas, and no additional emissions are generated.

- We use more efficient filters to capture dust and emissions (e.g. fluorofilters).

- The new equipment reduces the energy consumption of our firing process due to lower gas consumption and therefore CO2 emissions. One new production line currently replaces two original lines in terms of capacity and efficiency.

- Effective extraction of dust-producing production processes ensures that residual dust in the working environment is minimised.

- Our modern powerful extraction equipment allows dust to be reused in production. The new solution reduces dust in the working environment by almost 40%!

- After the installation of the new fluorine separator, the measured fluorine gas values improved by 56 - 83%.

- We reduce the thickness of ceramic tiles while maintaining the properties of the products and without limiting their use in practice.

- We reuse ceramic dust generated in certain stages of our production process, e.g. dry calibration, pressing, etc.

- We use unfired but also fired shards (broken, defective products from the production process) back in production.

- As part of the “circular” management of raw materials, we strive to maximise the return of ceramic dust - dusts that are generated in the various stages of production.

- Effective dust extraction allows us to return up to several tons of raw material per day back into the production process. At the same time, we reduce dust in the work area.

- The dry calibration of our products produces waste - dust, which is used back in production as a raw material for the production of ceramic sludge and thus used as a raw material for the production of ceramic tiles (the volume of dust is about 1.5 t per day).

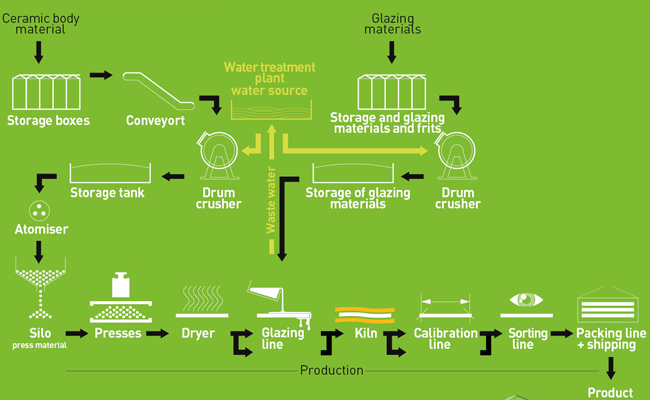

- Scheme of the production process from weighing the raw materials to packing our products on a pallet.

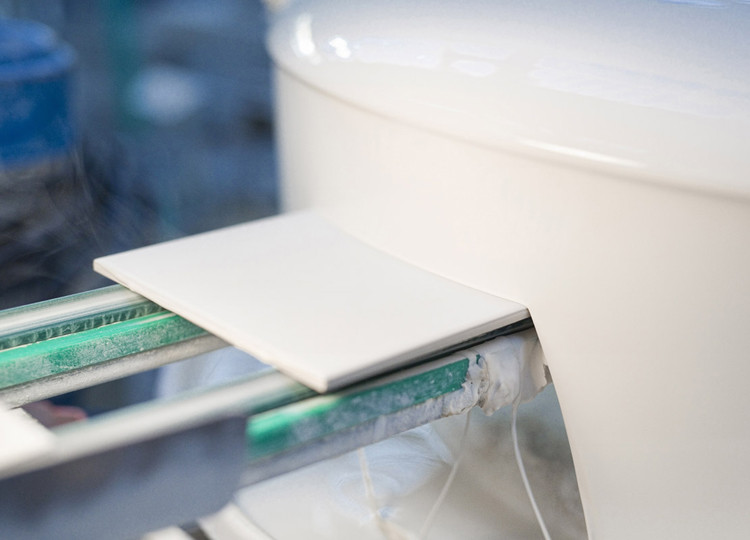

The raw materials are transported to the milling plant. The material that leaves the milling drum is a mixture of finely ground materials blended with water, from which a moist granulate is produced in dispersion dryers. The pressing of the granulate in hydraulic presses produces products that must be dried in a drying oven before their further processing. This gives the products the technological strength needed for further processing by engobing, glazing or further decoration.

The preparation of glazes and engobes is strictly separated from the preparation of working mixes of ceramic materials. They also work on the principle of wet grinding in drum mills. The engobe and glaze are applied with a suitable technology to the surface of the ceramic product.

At the end of the glazing line, the glazed and decorated semi-finished products are placed on transport vehicles, in which they are dried and transported to the ceramic kiln. The ceramic tiles are fired at temperatures of 1,000°C to 1,250°C.

After sorting, the products are packed in cardboard boxes and stacked on EUR pallets.

Download

- EU Ecolabel (PDF; 1.45 MB)

- CQS - ISO 9001 (EN) (PDF; 593.67 kB)

- IQNet - ISO 9001 (PDF; 662.08 kB)

- CQS - ISO 50001 (EN) (PDF; 592.58 kB)

- IQNet - ISO 50001 (PDF; 662.56 kB)