Raw Materials

Ecology and Environmental protection

-

We use recyclable packaging

We look for ways to reduce waste from packaging materials.

-

Natural raw materials

We produce environmentally friendly products.

-

We reduce CO2 from transport

Thanks to local sourcing, we reduce our CO2 production from transport.

-

Deposits close to our production

More than 95% of all the raw materials are sourced in-house.

The basic natural raw materials for the production of RAKO tiles are supplied by LB MINERALS, s.r.o.

They are mined in various locations close to our production plants.

- More than 95% of all the raw materials are sourced locally by mining our own raw material deposits.

- We minimise the risk of key raw material outages.

- RAKO is a reliable partner and supplier.

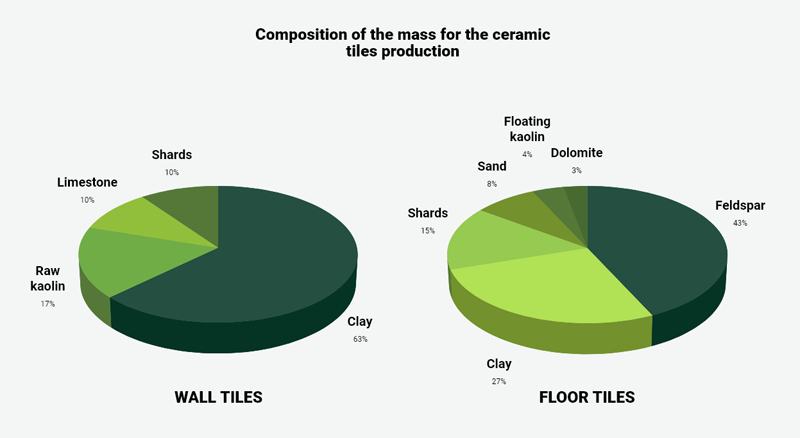

Nowadays, the production of ceramic tiles is very advanced, but it still cannot do without basic natural raw materials such as clays, kaolins, feldspars and sands. These raw materials for the production of RAKO tiles are almost 95% supplied by LB MINERALS, s.r.o. They are mined in various locations in the Czech Republic.

- The main supplier is LB MINERALS, a company that is part of the LASSELSBERGER Group and is a major mining organisation in the country.

- Its deposits are located in the Czech Republic, where the raw materials are mined and subsequently processed for the production of ceramics.

As the raw materials of LB MINERALS are reserved minerals and are part of the mineral wealth of the Czech Republic, their mining and processing are closely supervised by state authorities. The mining and processing of raw materials of LB MINERALS is carried out according to ISO standard.

The extraction of minerals has undergone rapid development in the past period. Today, our new processes are being applied that not only make the mining more efficient, but also contribute significantly to occupational health and environmental protection.

- Our ancestors already knew that it was advantageous to build processing plants producing ceramic tiles near mining sites. The LASSELSBERGER Group in the Czech Republic continues in this tradition.

- For the production of ceramic wall tiles, raw materials from local sources are preferably and almost 100% used, which significantly contributes to reducing CO2 production from transport.

We source more than 95 % of all our raw materials from our own sources.

- Mining and processing of clays, kaolins, and feldspars is based on physical and mechanical operations.

- No substances are added during the treatment process that would alter the nature of these raw materials.

Therefore, the raw materials for our ceramic wall tiles production are always purely natural materials at the end of the treatment.

Raw materials and glazes with minimal environmental and health impact are used for decoration and finishing.

Production effectiveness reduces the use of hazardous substances to the absolute minimum without negatively impacting product design. We are constantly searching the market for more natural and environmentally friendly alternatives to decorative raw materials (glazes) to support our continuous environmental improvement.

- LB MINERALS recognises that its activities are changing the character and appearance of the landscape and therefore places great emphasis on the remediation and reclamation of mined sites.

- LB MINERALS gives the landscape back to nature and people through its remediation and reclamation actions.

- LB MINERALS contributes to biodiversity.

- The new sites provide a habitat for rare species of flora and fauna.

- It returns nature to a form untouched by man.

Every year, LB MINERALS has approximately 50.000 new trees planted in the reclaimed areas. Our colleagues are looking for opportunities to sensitively use some of the areas for natural social space.

LASSELSBERGER also participates in the reclamation of the mined sites by using unprocessed shrapnel from our production process to backfill the mined sites. This returns the processed but unchanged raw material back to where it was mined (excavated).

- We strive to find ways to reduce waste from the packaging materials that LASSELSBERGER processes.

- We require returnable and recyclable packaging from our raw material suppliers.

- We apply effective changes to our waste policy and waste cycle. For example, we take wooden pallets for reuse.

- In the long term, we are looking for opportunities to use waste from other manufacturing processes involved in construction production (bricks, concrete, glass...), testing waste products from power generation and other projects.

What raw materials are used to make ceramic wall tiles?

Clay is a rock composed mainly of clay minerals, formed by the deposition of sediments in the lagoons of prehistoric rivers.

Every location has a different type of clay, which differs not only in its formation but also in its composition. As a result, different types of clays have different technological properties that allow them to be used in different industries.

What would not be produced without clay? Ceramic wall tiles and floor tiles, chimney systems, electro-porcelain, and utility ceramics. The production of refractory bricks, fireclay, masses, and crucibles cannot exist without quality clays. Clay cannot be omitted in the production of roof tiles and insulating bricks.

Kaolin is a whitish rock of sedimentary origin, formed by weathering or kaolinisation of feldspar rocks.

The extraction of kaolin from the mined material is a rather lengthy process, in short it involves sorting, sedimentation, pressing, drying, and grinding.

The use of kaolin is very diverse. The most common use of kaolin is in the production of ceramics, porcelain, paper, fibreglass, and sanitary ware. Its other uses include processing as a filler in various products, for the preparation of plaster paints, in the manufacture of pencils, sealants or as insulating material in the construction industry.

Feldspars are anhydrous aluminosilicates formed by the crystallisation of igneous rocks and are the most abundant rock-forming element in the Earth's crust.

Feldspars are valued especially for their alkali content, which dissolves the other components of the ceramic mass when heated to high temperatures and after solidification together forms a sintered or porous ceramic shard.

Feldspars are mostly used in ceramics, e.g. in the production of ceramic tiles, sanitary ware, porcelain, electro-porcelain, glazes, enamels or frits. They are also used in the production of packaging, utility, and flat glass.